4 Practical Reasons to join Pcb Repair Training Courses For A Bright Career

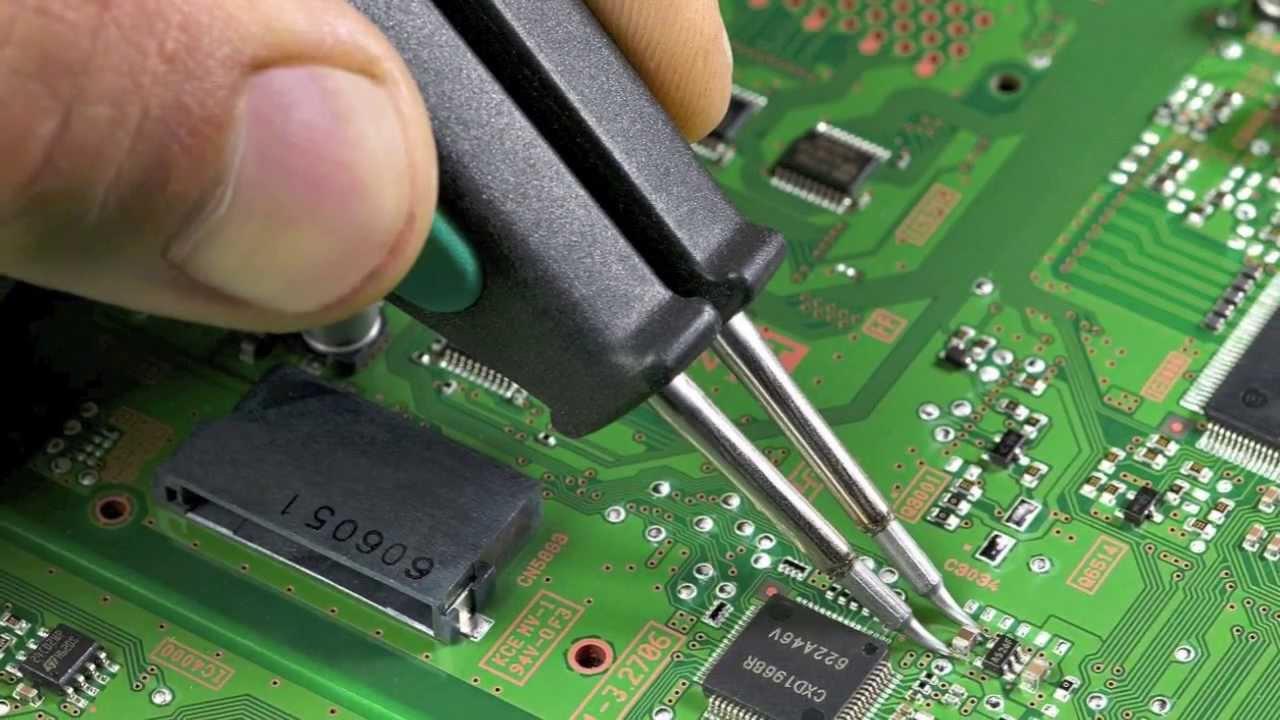

Technology is improving every minute, and the hardware necessary to support technological advancements is also getting better day by day. The modern Printed Board Circuit or PCB is the laminated sandwich structure of insulating and conductive layers. These have two functions:

- Soldering, affix the right electronic components at accurate locations on the outer layers.

- Establish a reliable electrical connection between the terminals of the components.

Unless someone hires the amateurs for the repair work, these boards have become an advantageous possession. If you want a prospective career option, you can join the Pcb Repair Training Courses that make you a certified professional repairing the PCB.

Reasons to learn the repair work

What’s the use of learning component-level board repairs for the PCB? You live in a generation where reusing is hardly an option. Tossing away the electronics in the landfill is not the right thing to do, especially if you have the option to repair them.

In fact, this is the first reason why repairing should be the primary option for people who are experiencing problems with the PCB. If you already have a passion for repairing electronic things, why don’t you join the training courses that teach how to fix the different issues of PCB?

You can find much satisfaction in the process of locating the affected tracks and identifying the failed board components, repairing them, or replacing them as store the PCB of you like to upcycle.

Need to learn

PCB repair is always the job of professionals. And you can be a professional easily if you join a good institute to undergo the training. Training is mandatory to handle something as complicated as a PCB, you have to learn about the object first. By joining the reputed training institutes, you will get to know about the structuring and functions of the PCB. Once you get conversant with the board, you will learn to distinguish between functional and non-functional ones. The target is to detect then differences and understand the cause-effect-solution cycle.

- Diagnosing damages

Identification of the problem with the PCB is as important as diagnosing the health problem by a doctor. Accuracy in diagnosis is achievable only through intense training about the ways to determine how to diagnose a problem step-by-step.

- You need to know the symptoms and the causes thoroughly to detect the standard problems.

- If the symptoms are not familiar to you, it is necessary to start eliminating the options process. Here, you will make a list of all probabilities leading to the problem and then start eliminating the options one by one after checking the related symptoms and glitches.

The training courses include teaching these techniques, which will result in quicker detection of the problems.

- Use of tools

Once you have learned how to detect the problems, the certified trainers will show you the different tools and equipment for repairing the PCB. It includes things like soldering guns, hot air gun adhesive copper tape, rubbing alcohol, tweezers, and many more such items.

The Pcb Repair Training Courses will teach you how to use each tool and when to use the right set of tools. The result is incredible, for much depends on what tool you are using for the repair work. Execution of the repair depends on how well you can handle the tools and apply the right one at the right time.

- Gather practical experience

One of the chief reasons to join the reputed training courses is to handle the real-life projects that will help you start your professional career independently. Experience is vital to ensure that you can gain reputation and better job roles in professional life.

You can give yourself chances of practical experience if you join the best courses for learning the PCB repairing mechanism. The process is elaborate and needs lots of patience. You have to develop the patience level, too, before being the hard-core professional.

- Certification is necessary

The IPC 7711/ 21 Certification program is mandatory to impart training to you if you are interested in replacing or repairing the physical damages to the PCB. Every client nowadays wants to see the certification to make sure that you have the necessary skill set to perform the repair work.

If you want to be a professional repair person, you have to know about the industry-approved standards for techniques of hole and surface mount rework.

Match the pace with technology

The continuous evolution in technologies will bring about more problems and demand innovative solutions. The training will help you face more challenging situations and handle them intelligently by combining your theoretical knowledge, practical skills, and logical mindset. It will make you the best professional in the industry.