Five Easy Steps to Repair a Hole in a Metal Roof System

Five Easy Steps to Repair a Hole in a Metal Roof System

Metal roofs are portable, lightweight, and durable but sometimes not affordable. These roofs are also stylish and give your property an appealing look with its vibrant colors and different textures. Due to these reasons, metal roofing has gained huge popularity in the last ten to fifteen years as the best material for roofing over a residential or commercial property.

As you should know that no material lasts forever, the metal roof also vulnerable to various threats, and there are going to be times when you have to check for the possible issues in your roof. There are potential issues that can be resulted in the leaking of the roof mentioned below.

- Damage from Weather

We have studied in the science books that metal has the property of contract and expand in different temperatures. The small changes in size and density of the metal can be the possible reason for the creation of the holes in the metal sheet of your roof.

- Poor Installation

Poor installation of your roofing can be the reason behind the damage of your roof. Many spots can be missed during the installation like omission of necessary caulking sealants and bar, no installation of an additional sealant strip at four-way panel laps, etc.

How to Patch a Hole in Metal Roofing?

When you talk about repairing the traditional roofing made of tiles or slates, it is easy to mend them and install new tiles for the damaged ones. But when people think about metal leak roof repair without any help from professionals, they tend to raise their eyebrows. Is it possible to patch a hole without any professional assistance? Yes, there five steps through which you can fix the issue as a homeowner.

What are the Required Tools to Mend the Roof?

The major tools that you should have to leak roof repair are- extension ladder, nail-bar, hammer, aluminum screw nails, wire brush, fabric shears, cordless drill, roof cement, plastic putty knife, paintbrush, and metal-roofing base coat. You can carry some minor tools in your tool-belt that can save your time and energy. Place your all heavy and necessary tools or material on the roof before your start the job.

There are the Following Steps to Repair a Leaking Roof-

Step-1 Identify the Issue

First of all, inspect your roof for the possible problems as it has one or two holes or is degraded severely. If you think that your roof has been damaged heavily, let’s not do it yourself. Pass the job to some professionals as they can be better in improving the condition of your damaged shelter. If it has one or two patches, read further to know the whole process.

Step-2 Clean the Area

Trash collected on the roof can make your job more difficult, especially around the damaged area that you are going to repair. Before you proceed to use your tools to patch up the hole, clean the area around the cavity in the metal sheet. Remove all the debris, dirt, and degraded remains of the layer. Prepare your work area by scraping away the coating with the help of a putty knife.

Step-3 Cut off the Replacement Sheet

When you are going to do leak roof repair, you will need a piece of galvanized metal sheet similar to the installed roof at your home or factory. In order to patch the hole, cut out the sheet bigger than the hole by 3 inches from each side. The bigger piece will be able to cover the complete hole, and the screwing part will also acquire some space.

Step-4 Drill the Roof

After putting the sheet on the cavity, drill both additional and installed layers together around the hole. Once you are done with drilling from every side, you can screw the piece of metal over the whole roof.

Step-5 Seal the Material

When you are done with screwing the metal sheet on the roof, it’s time to seal the outer edges of the patch completely. Seal it by applying caulk over the edges and then coat the ceiling for extra protection.

It is not a tough job when it comes to leak roof repair of one or two holes. But what if extensive damage has happened to your one or more roof panels? Simply, you have to change the entire roof panel to avoid any kind of a disaster at your place. Read further if you want to replace the panels of your metal roof.

How to Replace Panels of the Roof?

Step-1 Examine the Rafters

It is an initial step to replace the panel of your roofing. Carefully inspect the area below the roof and underlying rafters for any potential damage.

Step-2 Lose the J-rail

Once you are done with the inspection, you have to loosen the J-rail by removing the screws from both sides of the roof to put the new material there. Removing the J-rail completely will increase your hard work and will occupy the space unnecessarily. So, there is no need to remove it, slip the old section out by loosening the J-rail.

Step-3 Inspect the Interior

You need to examine the interior of your roofing through a flashlight to identify and mend the damaged insulation. With this, clean up the stagnant water under the interior, that could be the reason behind rusting the material.

Step-4 Replace and Cut the Sheet

Replace the damaged rafters with the old one and leave the attic to dry. After this, cut a new sheet of the same length and a foot wider than the damaged portion. The wider sheet from both sides will overlap the damaged area. After cutting the sheet in perfect shape, use some butyl tape on the bottom edges and place it on the degraded portion.

Step-5 Slide and Seal

Now, insert the end under the J-rail at both ends and insert long screws that can pass J-rail, new metal sheet, butyl tape, and the installed sheet of the roof. Now tightly screw the screws and seal the edges of four sides with the metal coating to prevent it from natural things like rain, hail, etc.

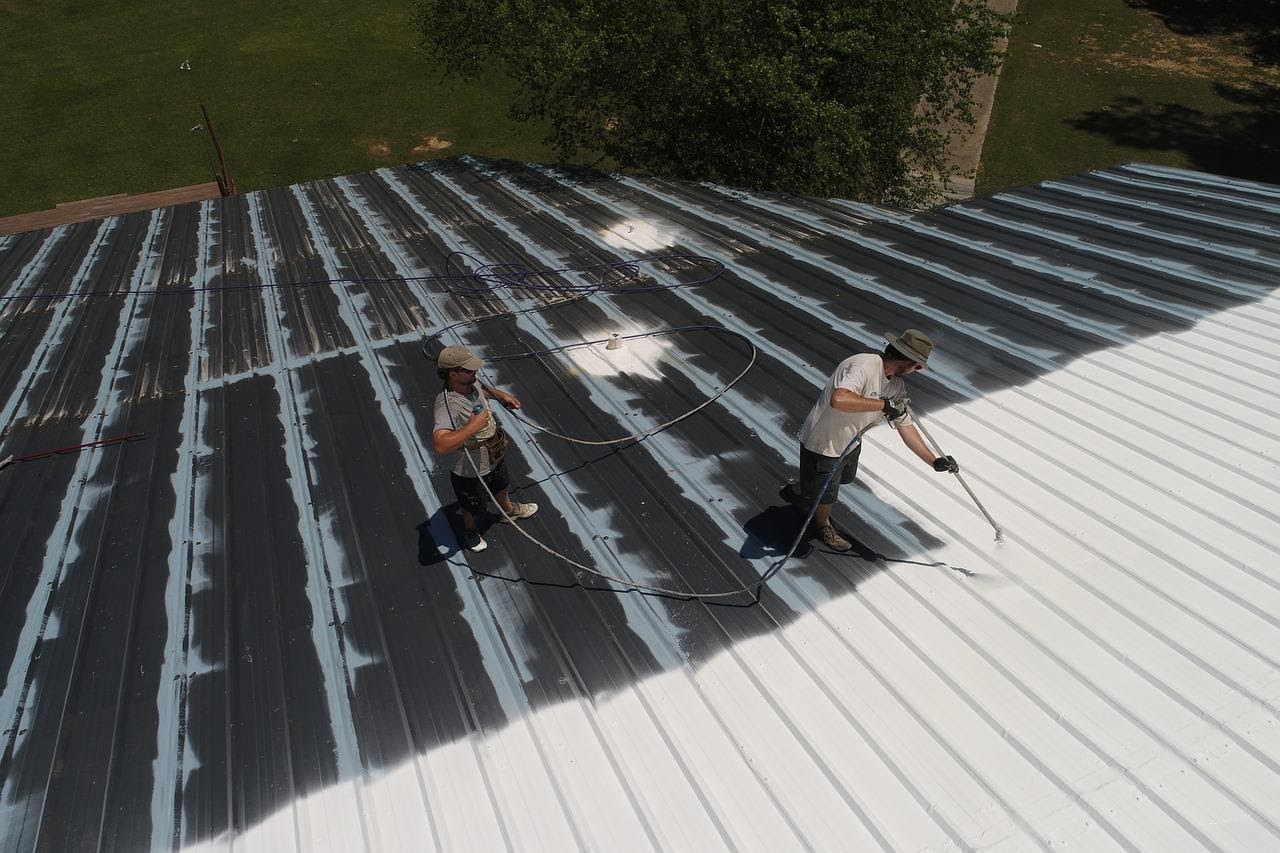

After Leak Roof Repair: Maintenance and Recoating

You should examine your metal roofing once a year. The metal coatings can get rust due to natural reasons, and the metal can be scratched with the time. These factors are the major reason behind the leaking of your roof. When you find any type of rust and damage, recoat the metal sheet by cleaning all the dirt and debris accumulated on the roof. Regular maintenance can save your money, time, and hard work.

If you’re not comfortable tackling the repair yourself, or if the damage is extensive, it might be time to consult an o’fallon roof replacement contractor. These professionals can assess the situation and provide expert solutions to ensure your metal roof is restored to its optimal condition. They have the experience and tools necessary to handle any roofing issue, from minor repairs to full replacements, ensuring your home remains protected from the elements. By choosing a reliable contractor, you can have peace of mind knowing that your roof is in capable hands, allowing you to focus on other important aspects of home maintenance.

Conclusion

You can seal one or more by following the steps for patching the cavity while you can also replace the entire panel of your roof. It is much better than paying a huge amount to the professionals as they can charge $7 to $12 for every square foot. And most of the contractors do the entire job for $616 to $1856. You can spend some time leak roof repair on weekends instead of watching a movie as you can spend this money on other necessary things.

If you find the repair process daunting or lack the necessary tools, it might be beneficial to consult with professionals who specialize in metal roof repairs. They can ensure the job is done correctly and efficiently, preventing further damage and extending the life of your roof. Should you need expert assistance, you can easily get in touch with experienced contractors who can provide the necessary services and guidance. This approach not only saves time but also offers peace of mind, knowing that your roof is in capable hands.